Industry 4.0 & LIMS Software: the role of LIMS on digitalized lab processes Design your Lab 4.0: LIMS automizes, digitalizes, and improves your lab workflows

You certainly heard of concepts like Internet of Things (IoT), cyber-physical systems (CPS), Industrial Internet of Things (IIoT), cloud and cognitive computing, Machine-to-Machine communication (M2M) and artificial intelligence.

In this blog, we will talk about many of these things related to LIMS software, which plays an interesting role in the Fourth Industrial Revolution. But, first, let us concentrate on the meaning of Industry 4.0 and the part of LIMS software.

Were you aware of the fact we are living in the middle of the Fourth Industrial Revolution?

The Fourth Industrial Revolution, or better known as Industry 4.0, was announced in 2015 by the German engineer and economist Klaus Schwab. The Fourth Industrial Revolution was the topic of the NGO World Economic Forum Annual Meeting in Davos-Klosters, Switzerland. Schwab emphasizes the advances in information technology and connectivity and the abrogation of human power in manufacturing processes.

We all know, the First Industrial Revolution started with the introduction of machines, chemical manufacturing, and iron production processes with the scope to increase the steam and waterpower. All in all, the first industrial revolution laid the basis for the modern capitalistic economy. The second industrial revolution was concerned with mass production and the use of electricity. The third one was characterized by electronics, IT systems, and automation, which set the fourth one’s prerequisites.

Therefore, Industry 4.0 is based on a cyber-physical system (CPS), a computing system that works thanks to a mechanism controlled by computer-based algorithms.

Transformed technologies have changed industries into smart manufacturing, which involve intelligent machines in their processes. What makes them so unique are interconnected supply chains: have you ever thought about machines making decisions on their own? What just a decade ago looked like a science fiction movie is now real. The introduction of robotics is also an upcoming theme in the Fourth Industrial Revolution.

Why LIMS for your Lab 4.0?

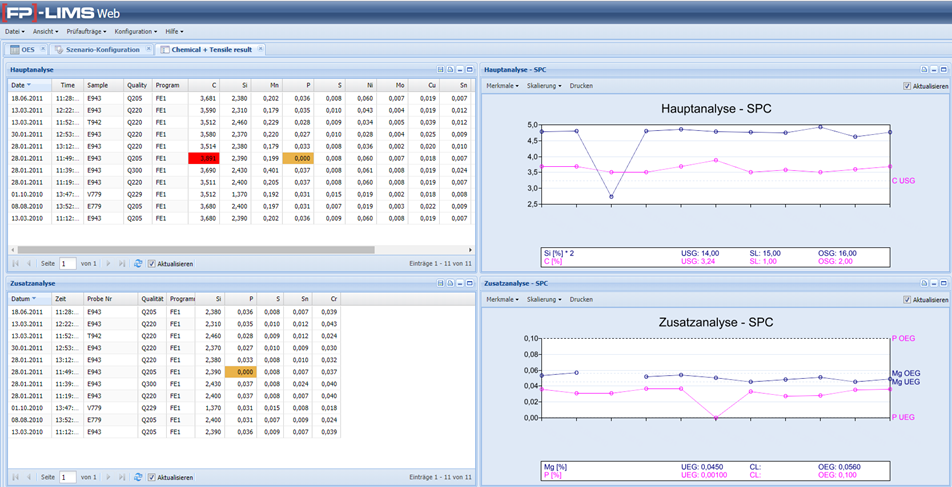

Taking on that Industry 4.0 optimizes the computerization of industry 3.0 and the upcoming of automatized processes in manufacturing, we should have a more in-depth look at the laboratory environment and its automation through the insert of LIMS software. LIMS means laboratory information management system, and the name itself already explains a lot of its function in a digitalized laboratory. LIMS software makes digitalized processes just more accessible by automatizing lab workflows. Managing data, tracking samples, statistical evaluation of your orders belong to the most common LIMS features. However, let us now look at [FP]-LIMS, the LIMS software solution designed by the German software developer Fink & Partner GmbH.

How can you get automatization and conformity to the upcoming standards, thanks to [FP]-LIMS?

[FP]-LIMS can communicate with upper-level systems like PLS and ERP. Since 2020 the solution has a certified interfaceto SAP S/4HANA®, the next-business generation ERP system for large enterprises. Hence, it is also possible to proceed with inspection lots, tests, and production orders for non-ending implemented digital laboratory processes.

[FP]-LIMS also supports the connection of various measurement devices, which automatically supply measurement data to the LIMS software. Laboratories usually evaluate, track, and elaborate data with MS Excel, which only requires the manual entry of data and numbers. It is very typical to make mistakes by using MS Excel. How many times you made a typo or just typed in the wrong result!

With [FP]-LIMS, you can avoid this problem. The reason for that is the digital way of measurement data from device to one database structure over, if your lab has it several different devices. Every data (Results, ERP data, sample information, etc.) is collected in one database. After its collection, it stands ready for next uses like generate automatic reports, certificates, and attestations, explicitly referring to test and production data. Test results of raw materials or pre-products can also be mapped into certificates, even if you have to collect a massive amount of data. Therefore, you can eliminate the “human-mistakes” factor and optimize your processes.

Besides, Fink & Partner’s LIMS allows you to assign your documentation, e.g. in lab notebooks, to the laboratory process, and keep it as audit-proof.

[FP]-LIMS is the right software four your Lab 4.0: it steps totally into digitalization and enables you access to your lab data through the web, thanks to its Browser interface module. The installation of LIMS software is a step toward the Fourth Industrial Revolution since it is also designed to reduce costs and to support digitalized laboratory quality processes.

To sum up, we can affirm Industry 4.0 mostly concerns the automation of manufacturing processes by reducing the use of human power and introducing cyber-physical systems, which are computing mechanisms based on algorithms. Installing LIMS software in your laboratory can be an upgrade to automize and digitalize processes we well as reduce your costs.