Quality management in automotive industry: Importance and usage

The automotive industry is one of the most important and largest industries in the world, so quality management of automotive parts and products is critical to ensure the safety of drivers and passengers. To maintain quality, automotive companies must have a system for inspecting, testing, and correcting defects. The most widely used quality management system in the automotive industry is Statistical Process Control (SPC). SPC enables companies to identify and correct problems before they become serious. This article informs about the importance and usage.

What is SPC?

Statistical process control (SPC) is a methodology used, among other things, in quality management in the automotive industry to ensure that products meet or exceed customer expectations. This should be done at minimum cost, i.e. with maximum efficiency. The goal of SPC is to identify and correct any process deviations that could lead to defects in the product. SPC relies on statistical analysis to identify trends and patterns in the data. This information can then be used to make informed decisions about how to improve the process. This data can be collected through software solutions such as a LIMS.

What is a LIMS and how can it help in quality management?

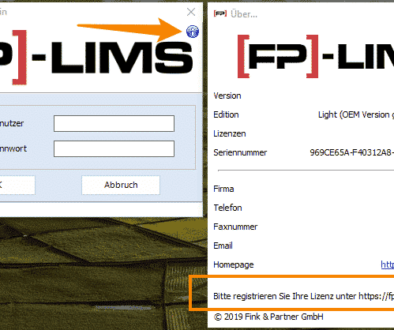

A LIMS, or Laboratory Information Management System, is a software application used in the automotive industry and other sectors to manage laboratory operations. A LIMS can automate many tasks in a laboratory, including data collection, tracking samples and results, and generating reports. In the automotive industry, a LIMS is often used to manage quality control processes, such as SPC. For example, a LIMS could be used to track the results of quality testing on parts or vehicles. This information can be used to improve quality control procedures and ensure that products meet customer expectations.

![[FP]-LIMS quality management in the automotive industry [FP]-LIMS quality management in the automotive industry](https://blog.fp-lims.com/wp-content/uploads/2024/01/FP-LIMS-quality-management-in-the-automotive-industry.jpg)

Advantages of FP-LIMS for quality management in the automotive industry

Thanks to its enormous flexibility and adaptability, [FP]-LIMS offers some advantages that competing LIMS cannot provide. Our software adapts to your current processes, we are happy to develop individual requirements such as interfaces to devices or higher-level data systems such as ERP systems on request. If your requirements change over time, you can extend [FP]-LIMS with our modules at any time. Each installation of our software comes with the basic module “Analysis Management”. The module all the basics for a successful quality management. Trends and patterns can be identified by means of graphs, and exceedances of tolerances by means of colored backgrounds. This allows you to react quickly to quality deviations and prevent potential costs and extra work. Our audit trail function helps to identify the causes of deviations, as it logs all work processes and makes them traceable. In addition, access rights can be defined to prevent unauthorized access to sensitive data. These and many other functions make [FP]-LIMS the ideal LIMS for quality management in the automotive industry.

- Flexibility and adaptability:

For example, freely customize parameters, units and workflows according to your preferences. Due to numerous standard interfaces and the possibility to realize individual interfaces, [FP]-LIMS can be used with almost all devices that output measurement data. In addition, connections with other data management systems such as ERP systems are possible. - Expandable at any time:

[FP]-LIMS can be extended at any time with our modules. If, for example, you have decided to automate processes outside the laboratory, you can supplement your [FP]-LIMS with our workflow management system and in the future have processes such as complaints or approval processes run automatically. - Trends and developments:

With our basic module “Analysis Management”, you have an overview of all current developments in real time. Thanks to colored backgrounds, quality deviations can be identified quickly and easily and countermeasures can be initiated. - Troubleshooting:

The audit trail function allows you to trace back all work steps and thus identify sources of errors in the shortest possible time and find solutions for them.

Do you have special requirements for LIMS software? Clarify them with us in a 30-minute demo appointment, in which we also offer you an exclusive insight into our software. This is, of course, 100% free of charge and without obligation. Let the experts advise you now.