WHAT IS NEAR INFRARED SPECTROMETRY / NIRS?

helpful in the analysis of molecules (NIRS)

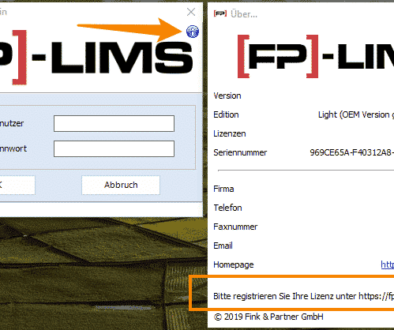

In a well-managed laboratory, structure and seamless documentation of all work steps are at the top of the agenda. A functioning data management system that works reliably and without flaws in the background is therefore also important. The Fink & Partner [FP]-LIMS offers you exactly this service with the addition of a maximum user-friendly interface and fast and uncomplicated access to all data. Thus, for example, the creation of a certificate or the clean visualization of some measurement runs is also possible spontaneously. This also applies to near-infrared spectrometry.

Near infrared spectroscopy, also known as NIR spectroscopy or NIRS, describes the process of a physical analysis method based on the short-wave infrared light. In general, near-infrared spectrometry works in the same way as infrared spectroscopy in the mid-infrared and far-infrared range – but with the difference that NIRS enables easier access, other forms of analysis and the use of other materials and radiation sources.

How Near Infrared Spectrometry Works

The NIRS principle is based on near-infrared technology. This produces electromagnetic radiation in the near infrared range, which stimulates molecular vibrations. Detection in near infrared spectrometry takes place in the so-called “near infrared range” (from 760 nm to approx. 2500 nm or approx. 13,000 – 4,000 cm-1). It is in this region that the overtone or combination oscillations of the fundamental molecular oscillation from the mid-infrared are located.

During the analysis of samples, the overtone and combination bands are not interpreted directly. They are evaluated with the aid of complex statistical methods. If the analysis aims at a quantitative determination, several data sets with a known content or concentration of the element to be analyzed are generated in advance of near-infrared spectrometry and in general for all infrared spectroscopy processes.

The advantages of near-infrared spectrometry clearly lie in the higher penetration depth of the near-infrared light due to its higher energy and thus easier handling. Sample preparation in near infrared spectrometry is also much less time-consuming and requires no upstream extraction or the like.

The fields of application of Near Infrared Spectrometry

The NIRS is a virtually perfect method for measuring the water content in products of various origins. However, near infrared spectrometry is used above all for quality analyses of agricultural products such as flour, oil fruits, milk and cereals and for the moisture determination of animal feed. Amino groups of proteins, CH bonds and fibres can also be determined in crude fibre analyses, COOH groups in plastics and CH bonds in the analysis of the fat content of a sample. In today’s industry, NIRS is mainly used in the food industry. For example, in the process of quality control in the manufacture of potato products. Near-infrared spectrometry is also used in pharmacy and science. In chemical companies it is mainly used for incoming goods inspection of raw materials and other delivered goods. A familiar picture of the NIRS application is the separation of composite materials and beverage cartons as part of waste separation. The different materials are detected within seconds by near-infrared spectrometers and then sorted.

Cooperating suppliers

Our LIMS is compatible with a large number of well-known manufacturers in the industry. Due to years of experience and the high demands on ourselves, we have extended the compatibility of the software in the past years more and more. Among others, the devices of the following manufacturers are compatible with our Fink & Partner [FP]-LIMS: Hitachi, Bruker, Spectro Ametek, ThermoFisher Scientific, Agilent Technologies, analytikjena, Horiba Scientific, Malvern Panalytical, Microtrac, PerkinElmer and Zwick Roell.

The Fink & Partner [FP]-LIMS in your laboratory

With the Fink & Partner [FP]-LIMS, you too can now bring an absolutely reliable and professional system into your business. In this way you not only ensure a more structured and efficient way of working in the future, but also relaxation for all employees in the laboratory who deal with the measurement data on a daily basis. Because if there is one thing that is absolutely dispensable in a laboratory, it is the confusion.