WHAT IS PARTICLE SIZE ANALYSIS?

How does grain size determination work?

The determination of grain sizes can be done by several methods. Basically, a construct called equivalent diameter is used for the analysis. The equivalent diameter assumes that the determinable property (in this case the diameter) is reflected in the form of spheres of equal size. Determinable means that the particles that pass through a sieve have the diameter of the diagonal of the sieve hole.

The choice of the particle size procedure method depends on the size of the particles. Large particles (from 63 mm diameter) are measured by hand, small particle sizes (10 µm) are determined by sieving. If the size ranges become smaller, methods that are technically more demanding, such as laser diffraction or dynamic light scattering, have to be considered.

These advantages bring data about particle sizes

Information about the grain sizes of a batch provides insight into material properties. These properties are important for technical and scientific use.

How is particle size analysis used in industry?

The grain size analysis method is used in industry to test quality. At incoming and outgoing goods, particle sizes are determined to determine the suitability of the material for further production steps.

For example, in the construction industry it is indispensable to check all types of bulk material. If size specifications are not met, weak points may occur, for example in the foundation.

Highly innovative measuring instruments for grain size determination

Microtrac is a well-known manufacturer of measuring instruments used in the field of grain size determination. The S3500, Bluewave and Tri-Blue instruments use laser diffraction technology. This established technique is used for quality control in the warehouse and in research and development. The laser beam penetrates a sample and the scattering of the light is a measure of the particle size distribution. Small particles ensure wide light scattering, large particles scatter the light at small angles.

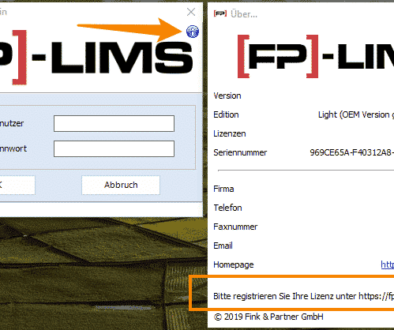

The data obtained during such a measurement can now be recorded and analyzed in a system. Fink & Partner is a provider of LIMS software, a system that stores and evaluates information. The laboratory information and management system plays an important role in particle size determination. The data obtained during the measurement is transferred to the Fink & Partner software as raw data through automated processes. The communication between the instrument and the system enables precise analysis and presentation of the results.

Not only in particle size determination, but also in all other measurement analyses and material testing, a powerful LIMS is a central prerequisite for productive work through efficiency in laboratories all over the world.

See for yourself the strength of the [FP]-LIMS

Would you like to find out more about how our [FP]-LIMS can increase productivity in your laboratory? Our experts will be happy to assist you with their experience. We look forward to hearing from you!