LIMS SOFTWARE FOR MACHINE-TO-MACHINE COMMUNICATION M2M MACHINE-TO-MACHINE M2M COMMUNICATION FOR YOUR LABORATORY 4.0

Find out more about Machine-to-Machine M2M communication and make your lab devices interact among themselves!

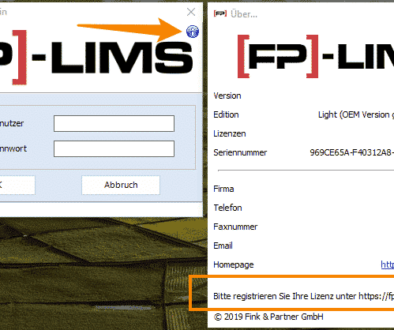

In a laboratory environment, measurement devices should interact with each other to make laboratory technicians spare their time and optimize their quality management processes. LIMS is the laboratory software that enables communication among devices and optimizes and improves internal workflows. In this article, we will analyze LIMS software’s role for an upgraded communication between “machines” for Lab 4.0. We will consider the case of [FP]-LIMS, the LIMS software solution developed by the German company Fink & Partner GmbH.

However, it is essential to clarify what M2M communication means explicitly and how it can be distinguished from the Internet of Things.

What is M2M communication?

M2M communication belongs to the fundamental roots of the manufacturing industry. Critical components of M2M systems are sensors, RFID, and autonomous computing software developed to support the network device to interpret data and make decisions.

What distinguishes M2M from IoT?

The fundamental difference between M2M and IoT is that M2M systems are often isolated and independent network instruments. Simultaneously, IoT devices are IP-based and have the purpose of sending data collected from connected devices to digitalized platforms, middleware, or gateways. Data collected from M2M-devices are made to manage application and affects the way companies operate. In contrast, data from IoT-devices affect end-users and are made to improved business performance across multiple groups.

What is the role of LIMS software?

LIMS means “laboratory information management system” and concerns laboratory software designed to enable communication between measurement instruments in the lab environment for high tech workflows.

Let us analyze the following examples to clearly explain how [FP]-LIMS enables M2M bidirectional communication.

A lab technician conducts optical emission spectrometry analysis and imports measurement data from his OES spectrometer. However, he or she has an extensive test order from various measurement methods, let us say XRFand hardness test. In order to have a global overview, the lab technician needs to import the data coming from those analyses as well.

In a Laboratory 4.0, automized communication between measurement devices belongs to the fundamental requirements. Let us now consider that we have an inspection lot from an ERP-system, and we are conducting the following analyses: OES, XRF, and hardness test. Thanks to [FP]-LIMS we can separate and send the pieces directly to the measurement machine, automatically collect all data and therefore automize the analyses. This coordinates the machines and stores the data into [FP]-LIMS, which sends to ERP the disposal decision according to pre-configured rules. Nevertheless, you can have access to the stored data through [FP]-LIMS anytime you need it. This is bidirectional communication, which implies no need of human interaction. Therefore, you can also consider [FP]-LIMS as the bridge to upper-level systems for your data integrity.

One last example to define M2M communication is the upcoming standard of robotics. For instance, OES automized robots are de facto an important piece of the automatization-chain. In fact, OES robots substitute people and have the task to provide the measurement device with the samples every day, all day long with no break needed and without human physical interaction.

All in all, to summarize, we can affirm that [FP]-LIMS is the key to communication between machines (M2M) because it can collect measurement data from the most various lab devices and can make them automatically interact with each other without any human interaction.